Airports Take the Lead Electrifying Transport

Airports are going electric.

Moving away from fuel-intensive ground operations, U.S. airports and airlines are embracing all-electric alternatives to power shuttle buses, parked aircraft, service vehicles and much more. The switch to cleaner operations is achieving reductions in air pollution and carbon emissions.

The transition can come with new sets of challenges. Infrastructure design must overcome capacity constraints and operational hurdles as resources and space for gate electrification and charging station projects can be highly competitive.

Fleet Electrification

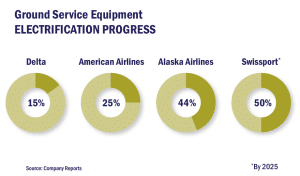

Airports have a long history of converting ground service equipment (GSE) to run on electricity. American Airlines was the first to undertake a major electric GSE (eGSE) conversion. In 2001, the airline replaced their complete fleet of fossil fuel powered GSE at El Paso International Airport.

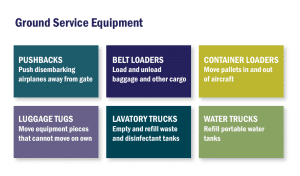

Major airlines have since followed suit, transitioning more than 10 percent of conventional belt loaders, cargo loaders, bag tugs and pushback tractors. In addition, many are replacing gas- or diesel-powered shuttle buses and security vehicles with battery electric vehicles (BEVs).

Port Authority of New York and New Jersey, for example, now manages the largest airport battery-electric bus fleet on the East Coast and intends to replace 50 percent of light-duty vehicles across LaGuardia Airport, Newark Liberty International Airport and John F. Kennedy International Airport.

To accommodate new fleets of zero-emission vehicles, dozens of U.S. airports have installed charging infrastructure — with at least 20 projects locating new chargers at the terminals. Some of the largest projects to date are found at Boston Logan International Airport, Dallas Fort-Worth Airport and Washington Dulles International Airport.

Electrifying Terminal Gates

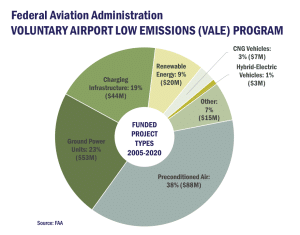

In addition to electrifying GSE fleets, airports are installing pre-conditioned air (PCA) and ground-power units (GPUs) to provide low-emission power while aircraft are parked. Aircraft otherwise typically use on-board turbine engines or ground-based, 400 hertz diesel-powered generators.

By electrifying terminals, airlines can warm and cool planes using pre-conditioned air units (PCAs) that run on nearby ground power units.

The conversion to electrified GPUs and PCA units is comparable to “shore-to-ship” projects taking place at marine terminals across the country. By relying on electric power, airports can avoid aircraft engine or generator-produced emissions.

More than a decade ago, Stewart International Airport in New Windsor, NY and Philadelphia International Airport were among the first to implement PCA conversions. Similar gate system improvements are now found nationwide. Southwest Airlines, for example, has electrified gate services at 62 of the 64 cities the airline serves.

Infrastructure Capacity Constraints

Older airport facilities can struggle to accommodate chargers or other supporting electrical infrastructure. Generally lacking power capacity, terminals of some age may only have sufficient capacity to accommodate light retail, dining and office functions.

Fleet and gate electrification efforts regularly involve installation of new substations, distribution contained within the substation, and electrical cabinets. To properly calculate load capacity, detailed studies must be undertaken, reviewing when the new electrical systems will draw power, at what power level and for how long.

These studies have led to creative approaches that minimized the need for additional airport infrastructure or, at a minimum, lowered initial electrical infrastructure costs. For instance, some airports have shared circuit capacity between GSE fleets and passenger boarding bridges — where electricity loads remain high though operation is not continuous— by installing proper interlocking controls.

In addition to capacity concerns, significant electrical system overhauls or expansions may be necessary to accommodate desired charging levels. Similar to the electrical system found across most garages, older terminals are frequently equipped with 208-Volt services. Though adequate for lighting and typical public area loads, rapid vehicle-charging systems generally require 480V service.

Limited Facility Real Estate

Airports must strike a balance between centralizing infrastructure and continuing the efficiency of critical operations.

Areas most critical for the safety and efficiency of transportation operations, mainly the apron area, tend to be ideal locations for chargers, power units and other electrification infrastructure. As a result, older airport facilities often lack the space and structural capacity for new electrical systems. Navigating this tradeoff requires careful review of terminal configuration, GSE operations, maintenance procedures and other apron traffic activities.

At one recent project, the operating airline ultimately prioritized charging system locations that avoided apron congestion and reduced GSE traffic. By placing chargers too far from the apron, however, the airline unintentionally discouraged operators from driving the extra distance to fully charge vehicles at the end of a shift. The responsibility was simply passed onto others, leaving them without a charge.

“Areas most critical for the safety and efficiency of transportation operations, mainly the apron area, tend to be ideal locations for chargers, power units and other electrification infrastructure.”

When updating electrical infrastructure within the terminal, a common challenge is finding space for transformers and switchboards. Many airports are reluctant to sacrifice terminal space for a transformer if they can otherwise use the area to generate revenue. Although environmental benefits from electrification may justify some disruption to airport facilities, project designers should be mindful that fuel savings not be eclipsed by unanticipated revenue loss or travel delays.

Importance of Long-Term Planning

Fortunately, power and space constraint challenges can be avoided, provided airports and airlines embrace the importance of careful, long-term planning. Thorough analysis is necessary to understand costs, operational impacts and potential financial savings.

Comprehensive plans can ensure infrastructure is sized and located appropriately, meeting demand and other operational needs. Long-term planning can also help facilities remain resilient and redundant to avoid potential power disruptions.

Given the various complications, cross-departmental collaboration is essential. Airport finance, planning and engineering departments should be engaged every step along the way.

With proper planning and collaboration, airport electrification projects will continue to take off. Whether motivated by clean-air mandates, carbon-reduction goals or an interest in avoiding fuel price volatility, these projects offer environmental and economic benefits for airports of all sizes. The future of airport operations is electric.

This article originally appeared in AAAE’s June/July Airport Magazine.