As Railroad Systems Advance, Wayside Signals Fade Away

From tungsten filament lamps to modern LED signals, generations of rail signal technologies have pierced through fog and darkness along U.S. railways. Today these relics of the railroad industry are rapidly disappearing. Advances in rail traffic signal controls are phasing out traditional train signals and their supporting wayside infrastructure.

Widespread implementation of Positive Train Control (PTC) has initiated this trend. In PTC-controlled territory, where PTC automates signal speed, enforcement of track speed, and safe train separation, the wayside signal system is beginning to move the wayside signals into the cab of the locomotive, along with other relevant data that assists the locomotive engineer in making critical decisions about what lies ahead of the train.

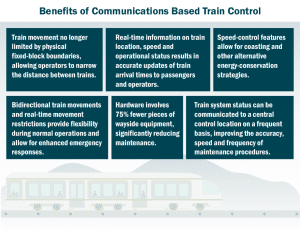

Communications Based Train Control (CBTC) will accelerate the removal of wayside signals. CBTC systems automatically inform dispatchers and trains about what is happening on the tracks ahead of the train. CBTC operators can rely upon onboard computers and modern telecommunications to address safety concerns and safely bring a train to stop before they occur.

Railways and rail transit systems are considering whether the redundancy benefits of keeping wayside signals is worth the costs.

As modern PTC and CBTC technologies gain prevalence, railways and rail transit systems are considering whether the redundancy benefits of keeping wayside signals is worth the costs to maintain these legacy systems.

Trends in Wayside Signaling

Expedited by the Rail Safety Improvement Act of 2008, PTC implementation has hastened removal of wayside signals over large stretches of tracks. When situations arise that may pose a safety risk, train operators now can rely on PTC with or without Automatic Train Control (ATC) cab signals to automatically bring the train to a controlled stop, rendering much of the legacy wayside signals as unnecessary pieces of hardware.

CBTC goes one step further, operating on radio communications to identify and automatically control multiple vehicle positions. Location information is relayed to each vehicle’s on-board computerized control systems, while monitoring each train’s speed, distance from other trains, and required braking distance. This allows transit operators to increase the number of trains running on the same track by narrowing the distance between trains — all without the guidance of wayside signals.

Modern CBTC installations have been completed on rail lines such as the New York City Transit (MTA) Manhattan-to-Queens Flushing Line and the Southeastern Pennsylvania Transportation Authority (SEPTA) Green Line. More are in development, including a $1-billion system on the Bay Area Rapid Transit (BART) Transbay Tube, as well as the SEPTA Media-Sharon Hill Trolley project now in construction.

Easier to Maintain at Lower Cost

To reduce maintenance costs and to minimize delays caused by signal failures, many train operators are removing wayside signal infrastructure altogether.

Traditional signaling hardware involves signal lights, wayside relay cases, relays, wayside instrument houses, dispatching offices, Centralized Traffic Control (CTC) machines, and miles of cable and track circuits. MTA estimates the continual upkeep and testing of trackside signals cost an average of $168,000 per track-mile per year. Much of those costs are labor expenses for work that can only be performed outside service hours.

Signal bridges, for example, typically need to be painted and strengthened. Track circuits are susceptible to weather and other environmental issues. For many older systems, replacement parts are often difficult to purchase due to obsolescence. Many parts may need to be custom ordered.

Copper cables stretching for miles along the wayside efficiently transport safety-critical data from location to location. To reduce the costs of copper wiring and related testing as mandated by the Federal Railroad Association (FRA), the railroads are investing large sums of money to transmit this data through more cost-effective mediums. Installation of Fiber Optic Cable (FOC) and wireless networking alternatives has encouraged further removal of wayside signals.

Legacy signal maintenance also involves significant operational costs. An in-service failure (ISF) occurs when a train is forced to come to a stop due to a track or equipment defect. U.S. railroads experience thousands of equipment-caused ISFs per year — sometimes caused by an event as simple as a burned-out signal light. For many subway services, signal problems are among the leading causes of delays.

Signal lights generally have circuitry to ensure quick detection of a burned-out bulb, with circuit logic ensuring that system safety is not compromised. However, the system will default to a degraded mode of operation — reducing speed or coming to a complete stop — which will affect overall system efficiency.

CBTC involves 75 percent fewer pieces of wayside equipment than fixed-block signaling systems.

Compared to fixed-block signaling systems, CBTC involves 75 percent fewer pieces of wayside equipment, significantly reducing maintenance interventions. New generation signal systems also include diagnostic capabilities of their own. Railway operators can pro-actively and remotely troubleshoot operational issues as the system identifies its own failed components.

Redundancy Benefits Questioned

Computer-Based Signal systems do not come without risk. Some system operators are choosing to keep legacy signal systems, known as Auxiliary Wayside Systems (AWS), in place for their redundancy benefits in case of communication network malfunction or other form of system failure.

Each railway must decide the level of secondary train-control system most appropriate for their operation. AWS equipment can provide partial back-up functionality relying, for instance, on track circuits or axle counters to relay track occupancy data.

But all systems are designed to include fail-safe operational characteristics. That is, in the event of a system or vital-component failure, all affected trains will be brought to a safe stop. Afterwards, for example, strict adherence to operating procedures such as speed reductions or train order operations can achieve acceptable, albeit degraded, levels of operations while maintaining system safety.

CBTC can completely replace conventional track circuit-based signaling systems without the installation of secondary, wayside or train-borne signaling equipment. A 2013 Federal Transportation Authority assessment of CBTC systems concluded, “There is no mandatory, overarching technical requirement to include a secondary train control system with CBTC.”

However, this FTA guidance is in direct conflict with FRA requirements. FRA maintains that track circuits are a safety-critical subsystem within the railway signal system that must be maintained at all costs. But many rail transit systems that are not part of the National Railway System do not fall under the authority of the FRA. In such circumstances, transit systems are instead subject to state oversight.

Safety-critical engineering and concern of system failure are major reasons why computer-based signal systems are considered to be so costly. As modern PTC systems become commonplace and comfort grows with the technology governing CBTC installations, concerns of the need for secondary signal systems may recede.

Signals Are Losing Steam

Some legacy wayside signal systems may remain in the rail industry for years to come. For many, advancements in wireless technology and GPS positioning technology will demand that the industry move to superior wireless, computer-based train control systems.

Financial considerations for system installation and maintenance will also pressure the industry to move forward. As State of Good Repair (SoGR) replacement projects progress across miles of rail and transit systems, legacy equipment will move into obsolescence.

And, like the steam engine — long ago replaced by technologically advanced diesel locomotives — signals are likely to become less common on the wayside and instead more prevalent in our railroad museums.