Planning the Transition to Carbon Neutrality

A thoughtful, comprehensive master plan is an essential tool for successfully achieving major reductions in a facility’s carbon footprint.

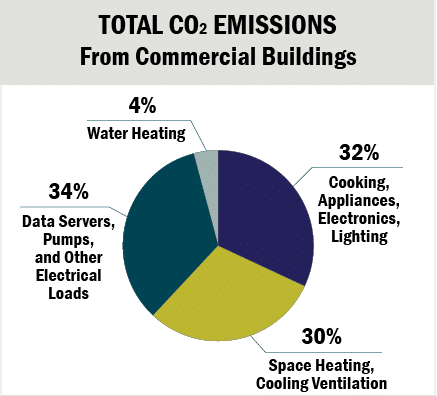

Unlike facility improvements of the past — mostly straightforward replacements of legacy equipment — electrification upgrades and alternative fueling solutions involve a more holistic approach. Decarbonization projects potentially require new sources of resilient power, energy distribution system overhauls, and integration of new and emerging technology solutions.

Whether for a corporate, municipal or higher-education campus, the decisions reached throughout the decarbonization process will dramatically reshape facilities and operations for generations to come. The level of effort dedicated to proactive planning will go a long way toward avoiding costly mistakes and greatly improves the likelihood of successfully achieving carbon neutrality commitments.

Decarbonization Challenges

More than one third of the world’s largest companies and over 1,000 educational institutions across the globe have pledged to achieve net-zero carbon emissions by 2050 or sooner. Their motivations are as diverse as the organizations themselves. Factors driving decarbonization initiatives range from increasing stakeholder demands to current and anticipated government mandates.

The transition may involve overhauling central plants to accommodate renewable energy solutions — or integrating decentralized, lower-temperature heating sources into district energy systems. Alternative heating solutions may also require major renovations of campus thermal and electrical distribution systems.

While the use of fossil fuels will decrease, the electrification of heating systems and the addition of new vehicle charging systems will drive up electrical demand. Power supplies will need to keep pace, potentially involving expansion of distribution infrastructure, transformers, and switching equipment. Microgrids will become increasingly practical solutions as campuses need more resilient, low- or zero-carbon power supplies.

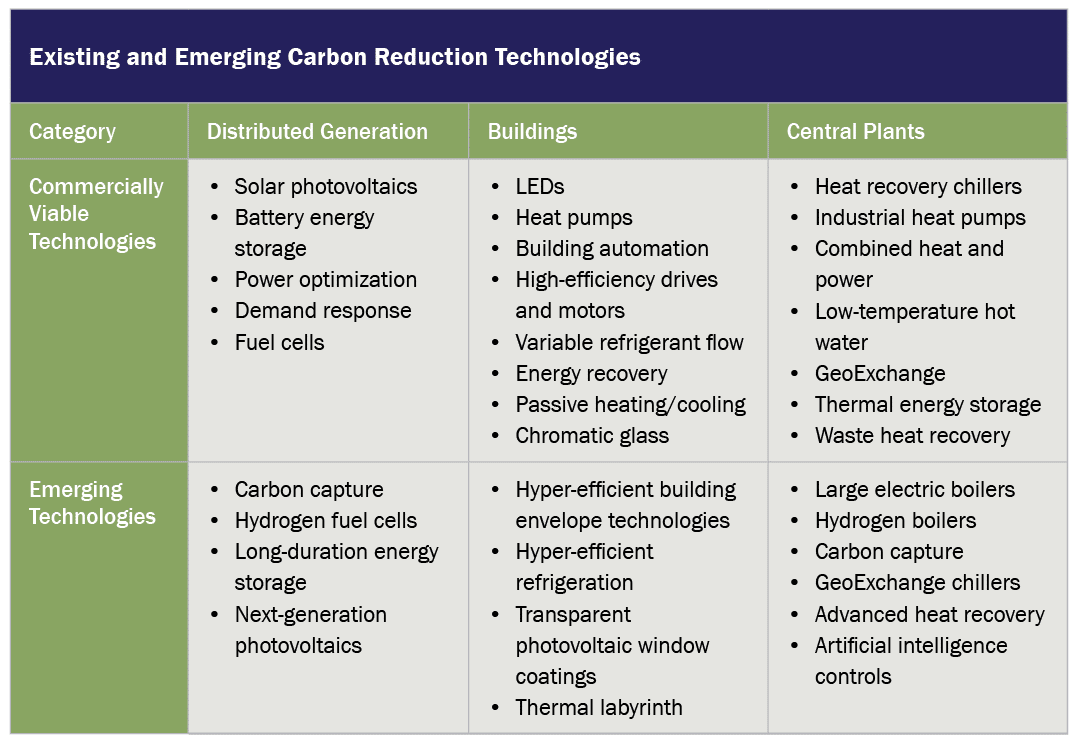

Such transformations may be plausible. A recent surge in climate tech venture funding has led to significant advancements in commercially viable renewable energy, building electrification, energy efficiency, and zero-carbon technology solutions. The planning process should include detailed analyses of these technology options to find the most appropriate engineering solution.

Decarbonization Master Planning Process

A typical campus master plan identifies and establishes the budgets for campus-wide construction projects. Decarbonization planning processes must be more comprehensive. The primary components of a thorough Decarbonization Master Plan include:

- Benchmarking Analysis: Establishes current and projected future energy consumption patterns, including energy conservation opportunities.

- Power Generation Potential: Calculates the total amount of zero-carbon energy that can be generated on site or at adjacent sites.

- Scenario Analysis: Evaluates carbon reduction impacts of multiple system/technology options and their associated life cycle costs.

- Technical Analysis: Assesses practicality of new and emerging technologies to identify each facility’s most effective and reliable solution. Categorization may include solutions ready today, in the next three years, or more than five years out.

- Transition Master Plan: Develops 10-year phasing strategy.

Source: Chronicle of Higher Education

Additional components may include:

- Infrastructure Assessment: Reviews condition and capacity of existing equipment and infrastructure.

- Power Forecast: Analyzes short-, medium- and long-term demand.

- Budget Forecasts: Projects future utility costs and other operational expenses, accounting for potential sources of new revenue.

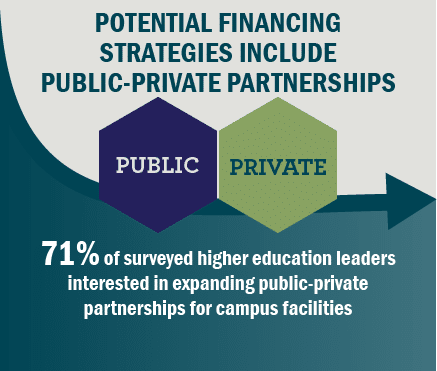

- Financing Strategy: Reviews conventional and alternative solutions, including reviews of energy-as-a-service and public-private partnerships.

- Operations and Maintenance Plan: Prepares for impact of new technologies, facilities and infrastructure on O&M protocols.

Typically, campus master plans are developed every five years with a 10-year outlook. Decarbonization plans may have to look out further, preparing for longer-term projects that may have greater scale and complexity than typical capital projects.

The master plan should take into account emerging financial incentives. Historic levels of federal, state and utility funding are now available for electrification initiatives. In New York, for example, Con Edison plans to invest billions of dollars to electrify 150,000 buildings by 2030.

A robust planning process can better position campus leaders to reap the benefits of alternative financing mechanisms. Through long-term lease arrangements, such partnerships can provide the capital necessary to modernize, operate and maintain energy and utility systems across the campus.

Emerging Hydrogen Fuel Technologies

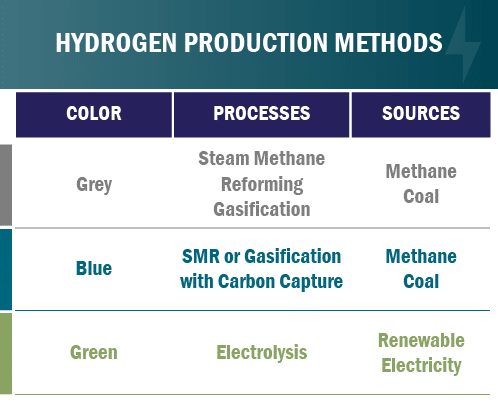

The challenges and opportunities of alternative fuels illustrate the importance of a robust strategic planning process. Hydrogen and renewable natural gas, for example, may soon become more feasible solutions for hard-to-electrify sectors, especially as fuel supplies expand and distribution networks improve.

The decarbonization planning process must take into consideration multiple factors when determining whether these solutions are best-suited for a given campus.

- Meaningful sustainability progress depends on how hydrogen is produced. Today, production relies mostly on fossil fuels such as natural gas. Federal investments are working to dramatically increase “green hydrogen” supplies. Green hydrogen emits zero carbon emissions, using an electrolyzer fueled by renewable electricity, but production currently remains very limited.

- Technology options may include converting from a natural gas-fired boiler to a “hydrogen-ready” boiler, which can still run on natural gas, or switching entirely to hydrogen fuel. Alternatively, a heating-fuel blend of up to 20 percent hydrogen can be used within existing infrastructure.

- Costs vary significantly, depending on whether existing HVAC systems are retrofit or replaced. Additional infrastructure improvements may include leak-detection systems, advanced ventilation, and electrical modifications that relocate potential ignition sources.

- Operations and Maintenance factors evaluate long-term costs and system durability. Introducing hydrogen to certain piping materials, for example, can make the metal more susceptible to cracking.

These are examples of factors to consider when planning a hydrogen project. Read more about electrification planning in Burns’ Guide to Decarbonizing College Campuses.

Future-Proofed, Resilient Decarbonization

When a robust planning process is combined with detailed engineering assessments, campus leaders are more likely to reach decisions that reduce costs and deliver long-term operational and financial benefits.

Advances in climate tech offer great promise. But the quickly changing technology landscape can easily lead to the selection of equipment that becomes obsolete within a few short years. All technology options have shortcomings — selections that may appear great on paper can be completely incompatible in practice.

Decarbonization master plans can help align internal and external stakeholders, design partners, and contractors, leading to solutions that withstand the test of time. Implemented effectively, the planning process serves as the long-term guide to cost-efficiently maintaining campus services, achieving decarbonization goals, and serving as a model of sustainable campus operations.